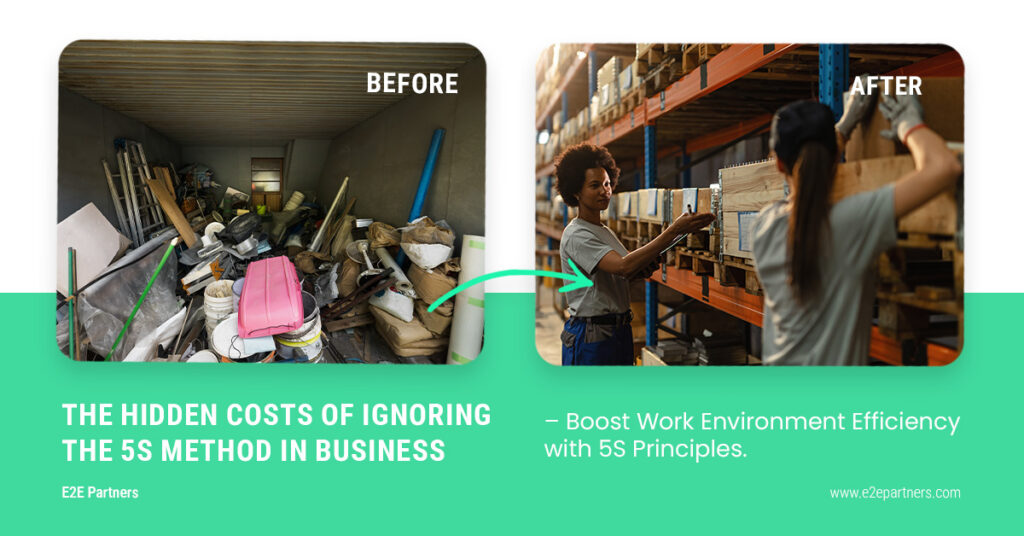

The Hidden Costs of Ignoring the 5S Method in Business

Ignoring the 5S method in your workplace may seem harmless, but it comes at a high cost, one that’s often hidden in plain sight. From cluttered workstations and wasted time to reduced productivity and inefficiencies, disorganization silently drains your business. In this article, we will explore how applying this method to work places can help eliminate hidden costs, streamline operations and boost long-term success.

What are the 5S Principles in Workplace Organization?

The 5S principles are a foundational part of a systematic approach to work organization and operational efficiency. Originating from Japanese manufacturing practices, this structured system is designed to enhance productivity, eliminate hidden costs and create a clean and efficient workspace.

Each principle of this method contributes to reducing waste, improving safety and streamlining operations. The five steps are:

Sort: Remove all non-essential items from the work-place to eliminate clutter and distractions. This step helps identify what tools, materials and equipment are essential, laying the foundation for better overall performance and space management.

Set in Order: Organize all the necessary items so they are easy to access and aligned with workflow. Clearly labeling storage areas and arranging tools logically ensures smoother operations and supports a more efficient environment.

Shine: Clean the work environment regularly to prevent dirt, hazards and equipment malfunctions. This step boosts morale and reinforces a sense of ownership, contributing to both safety and performance.

Standardize: Develop standard procedures for maintaining cleanliness and organization. These guidelines should be documented and shared, enabling consistency across shifts and departments. This stage is often reinforced through regular monitoring and reinforcement.

Sustain: Build a culture of discipline and continuous improvement. Encourage team members to follow established practices, and look for ways to improve the system over time. This ongoing commitment helps avoid common pitfalls that can derail workplace efficiency.

Why Is the 5S Method Essential in the Workplace?

Implementing the 5S method offers transformative benefits across your organization:

- Boosts Efficiency: A well-organized environment minimizes time spent locating tools and materials, speeding up processes.

- Enhances Safety: Clean, orderly workspaces reduce hazards and make it easier to follow safety protocols.

- Improves Quality: Consistent organization reduces errors and defects, raising product and service standards.

- Raises Morale: Employees are more motivated and productive in a clean, structured environment.

- Promotes Continuous Improvement: 5S fosters a mindset of ongoing evaluation and adaptation, which is essential for maintaining competitiveness.

Overall, 5S is a powerful tool for creating a more productive, safe and efficient workplace, benefiting both employees and the organization as a whole.

The Impact of Neglecting the 5S Method

Neglecting the 5S method can introduce serious hidden expenses that undermine both short and long-term organizational goals. Whether in manufacturing, offices, or service industries, failure to apply the method compromises productivity, organization, and overall system or process efficiency.

Here is how it negatively affects your operations:

Decreased Efficiency: Without 5S, employees waste time searching for tools, materials or information. This disorganization leads to slower workflows, bottlenecks, and reduced overall productivity.

Increased Waste: One of the core goals of the 5S method is to reduce waste, including time, motion, inventory, and defects. Ignoring these practices results in resource mismanagement and cost overruns that drain profitability.

Safety Hazards: A cluttered and poorly maintained workspace becomes a breeding ground for safety issues. Neglected tools, spills, and disorganized materials increase the risk of accidents, injuries, and costly legal consequences.

Lower Employee Morale: Employees thrive in structured, clean environments. A disorganized or poorly maintained workspace can discourage employees, resulting in a lack of engagement, exhaustion, and potentially high turnover rates.

Poor Quality Control: Inconsistent or absent standards make it difficult to deliver reliable results. The lack of standardization often leads to defective products and diminished brand reputation.

Customer Dissatisfaction: Inefficiency, missed deadlines, and product defects due to disorganization erode customer trust. In the long run, these failures impact repeat business and market competitiveness.

Cultural Resistance to Change: Organizations that overlook this system often lack the discipline and mindset needed to embrace broader process improvements. Without a culture of order and continuous improvement, future changes may meet resistance.

Rising Operational Costs: The cumulative effect of inefficiency, waste, rework, and safety incidents contributes to rising operational expenses—costs that could have been prevented through consistent application of 5S and regular evaluation.

How to Apply 5S in the Workplace

Implementing the 5S method is one of the first steps toward achieving operational excellence and process improvement. It’s not just a cleanup campaign, it’s a core component of lean manufacturing practices and continuous improvement. Steps to Implement 5S in the Workplace:

- Sort: Remove all non-essential tools and materials.

- Set in Order: Arrange remaining items in a logical flow that matches work processes. Adopt the mantra: “A place for everything and everything in its place.” This improves workplace efficiency and reduces time spent searching for tools.

- Shine: Maintain a clean environment through regular cleaning routines and inspection. A spotless workspace boosts morale and reduces safety risks.

- Standardize: Establish checklists, labeling systems, and workflows to ensure consistency. Use visual tools like color codes or shadow boards to uphold 5S standards and reinforce quality control.

- Sustain: This is where many 5S initiatives fail. Create a culture of continuous improvement by assigning responsibilities, providing support to sustain changes, and involving everyone from team members to business leaders.

Proper 5S implementation fosters a disciplined workplace, enhances organizational performance and supports cost reduction and quality of your work across all business processes.

Common Pitfalls to Avoid When Implementing the 5S Method

While the benefits of the 5S are widely recognized in the manufacturing industry and beyond, many organizations stumble due to avoidable errors. Recognizing these common mistakes is critical for success.

What to Avoid:

- Lack of Leadership Support: Without business leaders actively backing the 5S program, efforts often lose momentum.

- Inconsistent Follow-Through: Implementing the 5S is not enough. Without regular monitoring, training, and updates, standards deteriorate.

- Overcomplication: Avoid turning the system into a burden. Keep the 5S process simple, practical, and aligned with team roles.

- Neglecting Employee Involvement: A collaborative environment is vital. Employees must feel part of the process to fully commit.

- No Clear Monitoring Strategy: Skipping a proper monitoring process allows bad habits to return unnoticed.

- Failure to Connect 5S to Business Goals: Without linking the 5S methodology to cost savings, customer satisfaction, or product quality, staff may see it as busy work rather than a tool for improving workplace performance.

These errors can prevent your company from realizing the full benefits of the 5S method and compromise overall operational effectiveness.

Conducting a 5S Audit: A Step-by-Step Guide

A 5S audit is a systematic evaluation of your 5S workplace to ensure ongoing adherence to standards. It’s also a key element in quality management, lean practices, and standardize and sustain efforts.

How to Conduct:

Create a comprehensive checklist that covers visual cues, workspace layout, cleanliness, labeling, and overall organizational standards.

Define Roles: Assign a cross-functional team, ideally including members from different departments, to bring diverse insights.

Assess Each Work Area: Use a scoring system to rate workspace organization, safety, cleanliness, and standardization.

Document Observations: Take photos, note deviations, and track impact of 5S on key metrics like productivity and cost reduction.

Review with Staff: Share results and explain how they tie into operational efficiency and maintenance of high standards.

Develop Action Plans: Assign responsibilities and deadlines for correcting any deficiencies found during the assessment process.

Regular assessments not only prevent decline in standards but also foster a culture where quality standards and efficiency are consistently met.

Sustaining 5S for Long-Term Organizational Success

The real value of the 5S methodology lies in its ability to drive ongoing business improvements, but only if it is sustained. Many 5S initiatives lose steam without a strategy to reinforce and refresh the system.

How to Sustain 5S Effectively:

- Leadership Engagement: Ensure business leaders regularly participate in reviews and reinforce expectations.

- Ongoing Training: Educate both new hires and existing staff on 5S standards and their role in quality improvement.

- Kaizen Events: Integrate kaizen (continuous small improvements) into your routine. This ties 5S to broader lean management goals.

- Recognition Systems: Celebrate teams that excel in 5S compliance and improvements. This boosts engagement and morale.

- Digital Tools: Use 5S tracking software or visual dashboards to maintain accountability and streamline the implementation .

- Integrate with Six Sigma and Lean Tools: Combine 5S and Six Sigma for a comprehensive quality management system.

By fostering a culture of accountability and continuous learning, organizations create an orderly environment that supports manufacturing excellence, enhances customer satisfaction, and reduces operational costs.

5S Success Stories: Real Results from Organized Workspaces

Across industries, from the manufacturing sector to service-driven business environments, the implementation of 5S has delivered measurable improvements in operational efficiency, cost savings, and product quality. These 5S success stories highlight how applying the 5S method fosters an orderly environment, reduces waste, and transforms workplace culture.

Case Study: Toyota – The Benchmark for 5S in Lean Manufacturing

Toyota’s use of the 5S method is a cornerstone of its lean manufacturing practices. By strictly following these principles, Toyota has cultivated a disciplined workplace that supports kaizen and quality improvement. This approach minimizes the need for constant supervision, enabling self-managed teams that meet high quality standards and deliver maximum operational excellence.

Case Study: Nike – Streamlining Global Operations with 5S

Nike implemented 5S method across its manufacturing and distribution centers to support lean operations and reduce waste. By organizing workstations, optimizing storage, and embedding standard procedures, Nike improved inventory accuracy, reduced lead times, and lowered safety incidents. Empowering employees to take ownership of daily 5S routines helped sustain the improvements, leading to lower operational costs and smoother workflows.

Conclusion: Why You Can’t Afford to Ignore the 5S Method

The 5S methodology is more than a housekeeping tool, it is a strategic framework for building a cost-efficient, high-performing and resilient organization.

By integrating 5S into daily operations, businesses unlock:

- Lower operational costs

- Better product quality

- Safer work environments

- Stronger employee engagement

Most importantly, 5S fuels a culture of discipline and continuous improvement, the core ingredients for long-term growth. Don’t treat it as optional. Make 5S part of your business DNA.

Tania Chimbiro

E2E Partners